What are the advantages of hot melt dispenser in hot melt se

作者:點膠機廠家 日期:2020-02-13 10:21 瀏覽:

Many parts (accessories) of automobile manufacturing need the help of dispensing equipment. This time, we want to explain the function of hot melt dispensing machine in product manufacturing in a precise and effective way of hot melt sealing

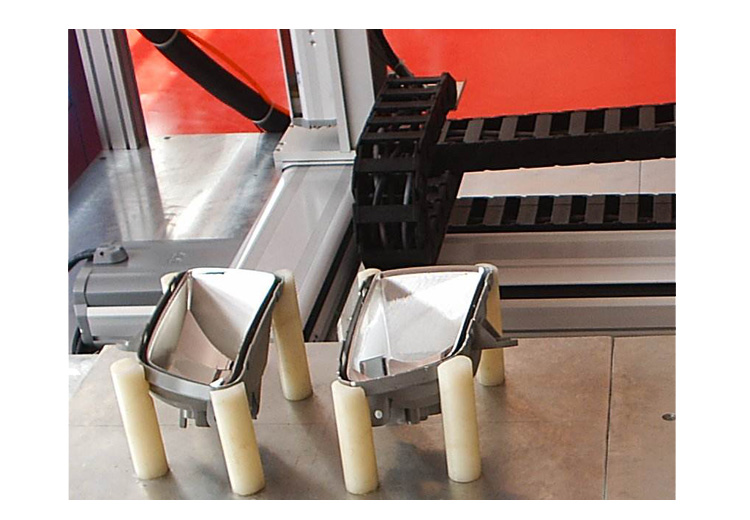

Desktop hot melt dispensing machine

1. Headlight

In the past steps, the headlight was basically sealed with rubber sealing strip with holes. The sealing was tightened according to the screws. After the hot-melt adhesive seal was switched, the sealing could be quickly glued, which not only reduced the cost but also facilitated the intelligent production. In addition, the sealing effect was better.

2, car chair

In the past, the production of car and chair basically determined that the hemming, lock catch and other mechanical steps would stabilize the seat cover and the frame together. At present, the hot melt adhesive is used to seal and glue, which can not only reduce the displacement situation, but also do a good job in semi-automatic production, greatly reducing the cost.

Built in lamp

3. Automobile instrument panel ventilation duct

After the car dashboard and cardboard parts are bonded, a cavity ventilation channel is generated. In the past, they were linked with larger staples, which not only consumed the workload, but also sealed poorly. After hot-melt adhesive sealing, the working efficiency was enhanced and the performance was ensured.

4. Car accelerator

The accelerator of car is made of polypropylene material. Because of its wear resistance, a polyformaldehyde disc needs to be bonded in the concave. This disc is a kind of hard to stick material, which can only be bonded with hot-melt adhesive.

5. EPC for intake pipe of automobile engine

The intake pipe of automobile engine is made of aluminum profile, and the production is to determine the foamed polystyrene lost foam. Because of the hollow structure, the two parts need to be bonded into a kind of synthesis, which needs to be completed in more than ten seconds. In addition, the adhesive needs to disappear with the polystyrene polyurethane foam at the same time under the aluminum water temperature, and the determination of EVA / vinegar based hot-melt adhesive seal is particularly satisfactory.

The operation of hot-melt glue dispenser has solved most technical problems in the field of automobile dispensing, enhanced the sealing efficiency of automobile parts production, and also made the automobile comprehensive production more beautiful and comprehensive. Hot-melt glue dispenser is an extremely important hot-melt glue sealing process equipment in automobile production and application.